Solutions Made Solid

Dynacast works with organizations all over the world, helping bring their ideas to life with the highest quality die cast components on the planet.

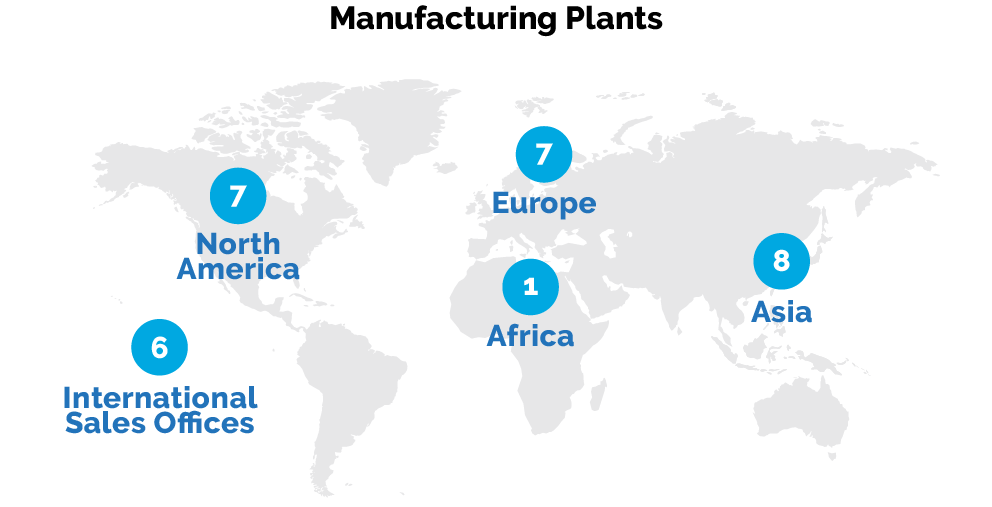

Manufacturing Plants

Countries

Faster Cycle Times

Expensive problems

With many manufacturers, customers have to forfeit lightweight designs for big, bulky components or bear higher part prices because of costly machining, all while sacrificing valuable turnaround time—even worse if they want to produce large volumes.

Dynacast’s in-house innovation changes everything.

Our solutions

With Dynacast’s proprietary multi-slide process, our design for manufacturing (DFM) expertise, and our manufacturing setup replicated around the globe, customers can create net-shape parts without secondary operations—including highly complex, thin-walled components normally manufactured from multiple pieces—and launch their products anywhere in the world, up to 10 times faster.

Discover Dynacast

Dynacast works with organizations all over the world, helping bring their ideas to life with the highest quality die cast components on the planet. Customers can come from virtually any industry—consumer electronics, automotive, healthcare, or any other where only the very best is good enough.

And each benefits from our 80 years of experience pioneering the techniques and technologies that have redefined the industry.

Company Snapshot

The Dynacast Difference

Proprietary Technology

- Dramatically faster cycle times (up to 10x)

- Longer shot life

- Increased efficiency in materials and processes

Engineering Expertise

- Tool design, quality, and process engineers in all locations

- Localized support across the globe

- Highly trained process and material experts involved in design phase

Local and Global Scale

- Standardization across global network of manufacturing plants

- Equivalent equipment, technology, quality systems, and engineering capabilities in all locations

Our Customers

Case Study

Helping our customer achieve <1mm wall thickness

The project: Solid State Drive for Enterprise Servers

Customer need: Thin-Walled Aluminum

The Dynacast solution: Proprietary process control

Utilizing unique tool design and special purpose CNC machining, achieve < 1mm wall thickness, maintain 0.1mm to 0.15mm/150mm length on flatness

Ready to change the future?

Rewarding careers in precision engineering

Dynacast is the world leader in precision metals design and manufacturing. Put simply, we help forward-thinking companies the world over create more innovative, higher performing products.